Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚙️ Cut smarter, last longer — the ultimate edge for pros.

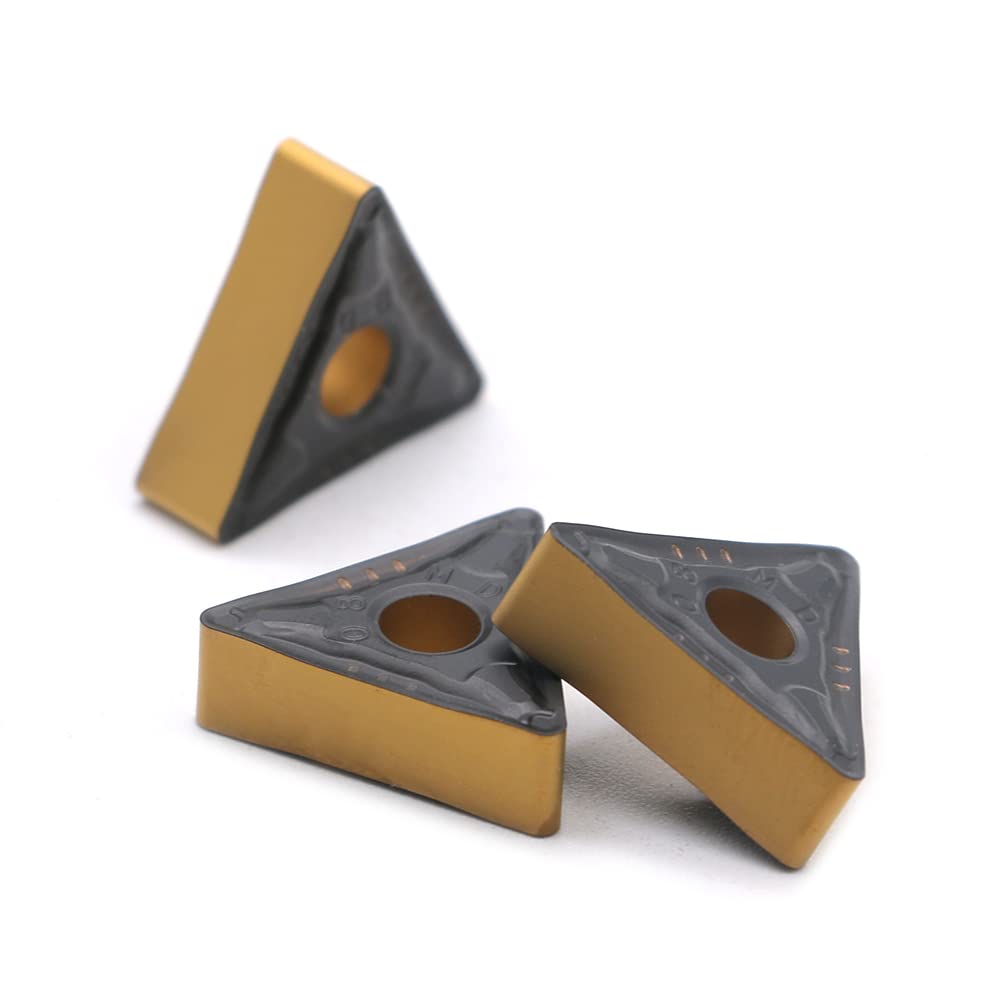

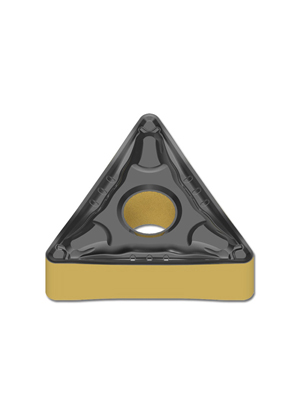

The TNMG332 CNC carbide inserts feature a 9.525mm diameter and 0.8mm nose radius, engineered for semi-finishing carbon and alloy steels. Enhanced with a cutting-edge MTCVD composite coating and thick a-AL2O3 film, these inserts deliver exceptional wear resistance and tool life. Their versatile design supports machining of steel, cast iron, and exotic alloys at high speeds, maintaining surface quality and stability across multiple turning applications.

Trustpilot

1 week ago

3 weeks ago

4 days ago

5 days ago