Customer Services

Copyright © 2025 Desertcart Holdings Limited

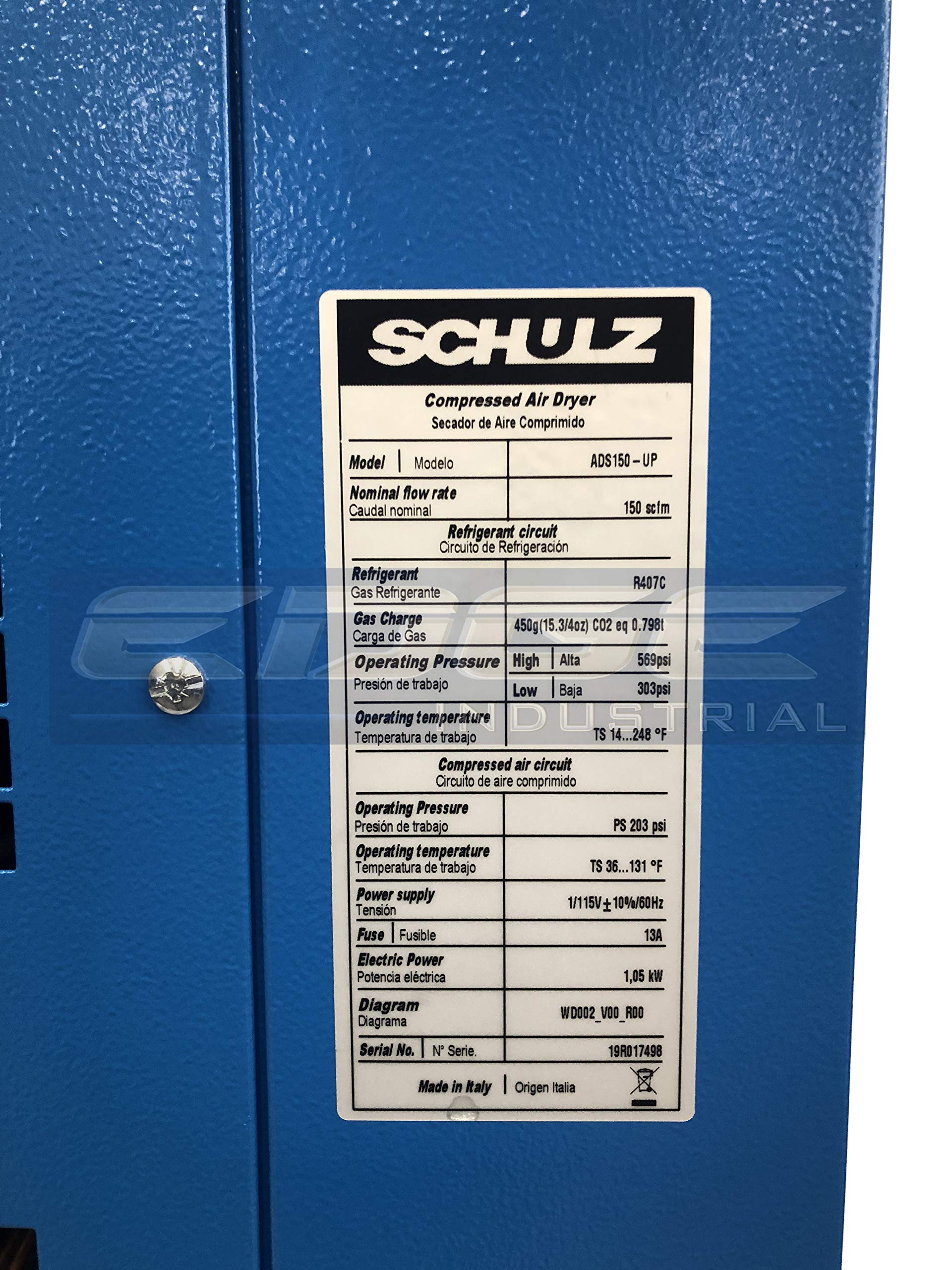

COMPRESSED AIR CONTAINS NATURALLY OCCURRING MOISTURE, WHICH CAN NEGATIVELY AFFECT COMPRESSED AIR APPLICATIONS THAT REQUIRE MOISTURE FREE AIR. DRYERS ARE A COMMON SOLUTION FOR REMOVING SUCH MOISTURE. ONE OF THE MOST POPULAR OPTIONS ARE REFRIGERATED AIR DRYERS, DUE TO ITS ABILITY TO REACH AN ACCEPTABLE DEW POINT IN. NON-CYCLING REFRIGERATED DRYERS, THE REFRIGERANT ACTUALLY CIRCULATES CONTINUOUSLY THROUGHOUT THE SYSTEM. BECAUSE BOTH THE FLOW OF COMPRESSED AIR AND AMBIENT TEMPERATURES VARY, A HOT GAS BYPASS VALVE IS USED TO REGULATE THE TEMPERATURE OF THE REFRIGERANT WHILE PREVENTING FREEZING WITHIN THE SYSTEM. IT IS VITAL THAT LIQUID WATER AND OIL ARE REMOVED FROM YOUR COMPRESSED AIR LINES BEFORE ENTERING ANY REFRIGERATED AIR DRYER. LIQUID WATER AND/OR OIL FROM YOUR COMPRESSOR CAN DAMAGE THE INTERIOR COMPONENTS OF THE DRYER RESULTING IN DRYER NON-PERFORMANCE OR FAILURE. WHEN YOU SELECT THE " WITH REGULATOR PRE-FILTER OPTION" WE PROVIDE YOU WITH A STAGE 1 WATER SEPARATOR WITH 3 MICRON FILTER ELEMENT AND INTERNAL FLOAT DRAIN BY ARROW PNEUMATICS. PART NUMBER F329-12WF3 PLUS DBK10 WALL MOUNTING BRACKET & HIGH FLOW REGULATOR 10-250 PSI ADJUSTABLE ARROWN PNEUMATICS PART NUMBER R3912 WITH GAUGE, CLOSE NIPPLE AND PIPE TAPE.. ADS DRYER INFO: 1-PHASE 115V, 14 AWG WIRE REQUIRED, DEW POINT: 41 DEGREES FAHRENHEIT AT 100 PSI, REFRIGERANT FLUID TYPE: R134a, DRYER IS 110 LBS

Trustpilot

2 weeks ago

2 weeks ago