Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

🔧 Connect with Confidence!

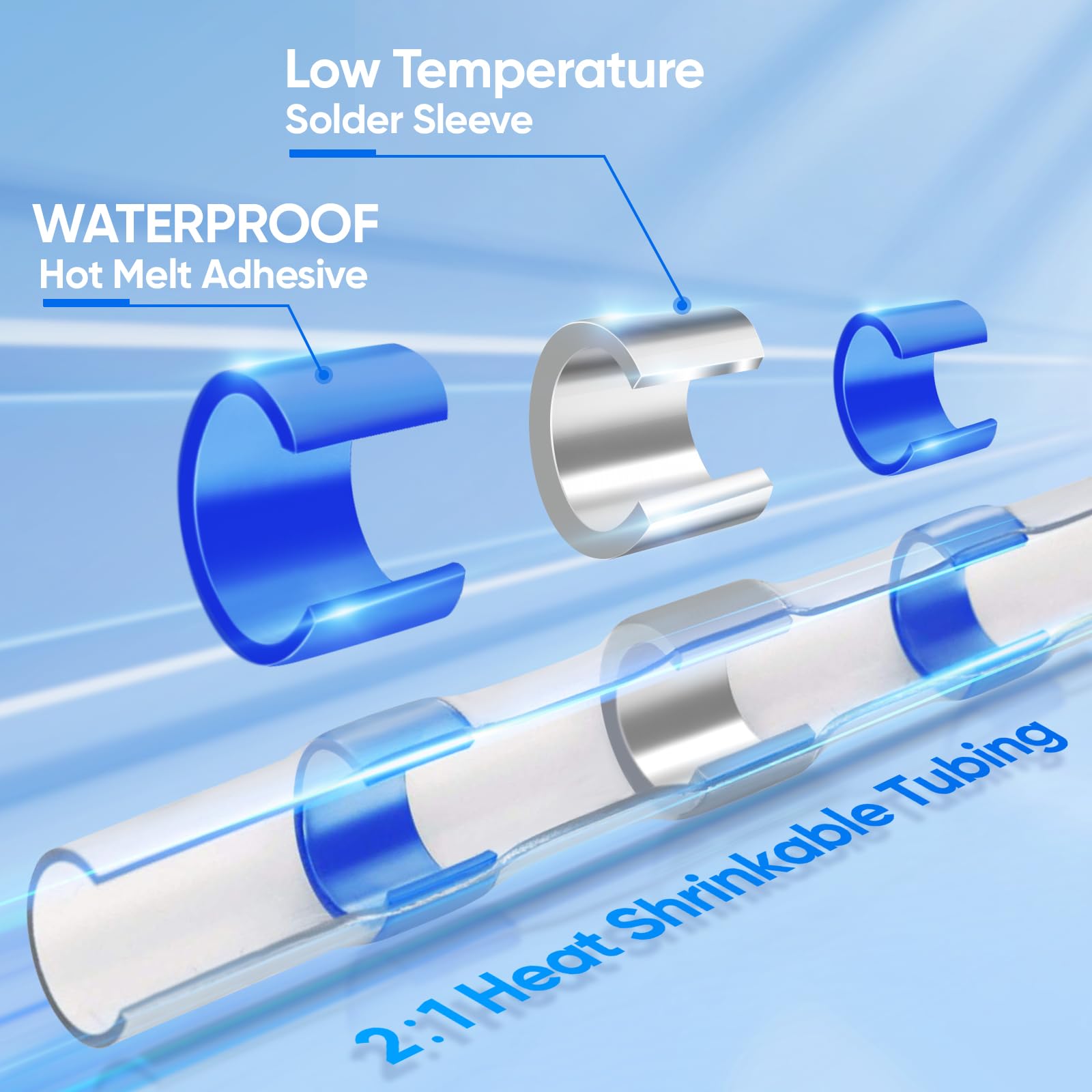

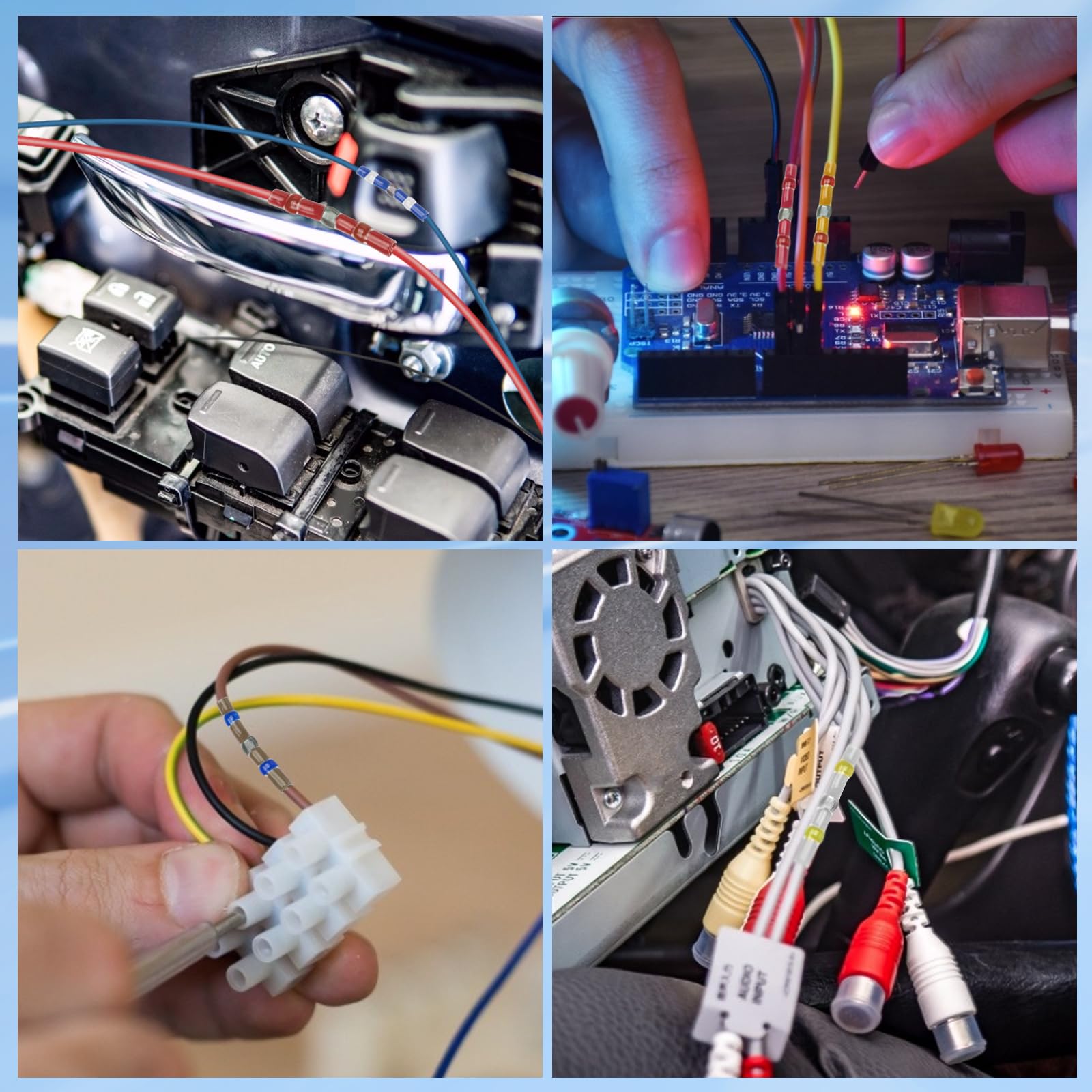

The TICONN 100PCS Solder Seal Wire Connectors are designed for professionals and DIY enthusiasts alike, offering a waterproof, insulated solution for all your electrical wiring needs. With 100 connectors in one pack, you can tackle any project with ease and reliability.

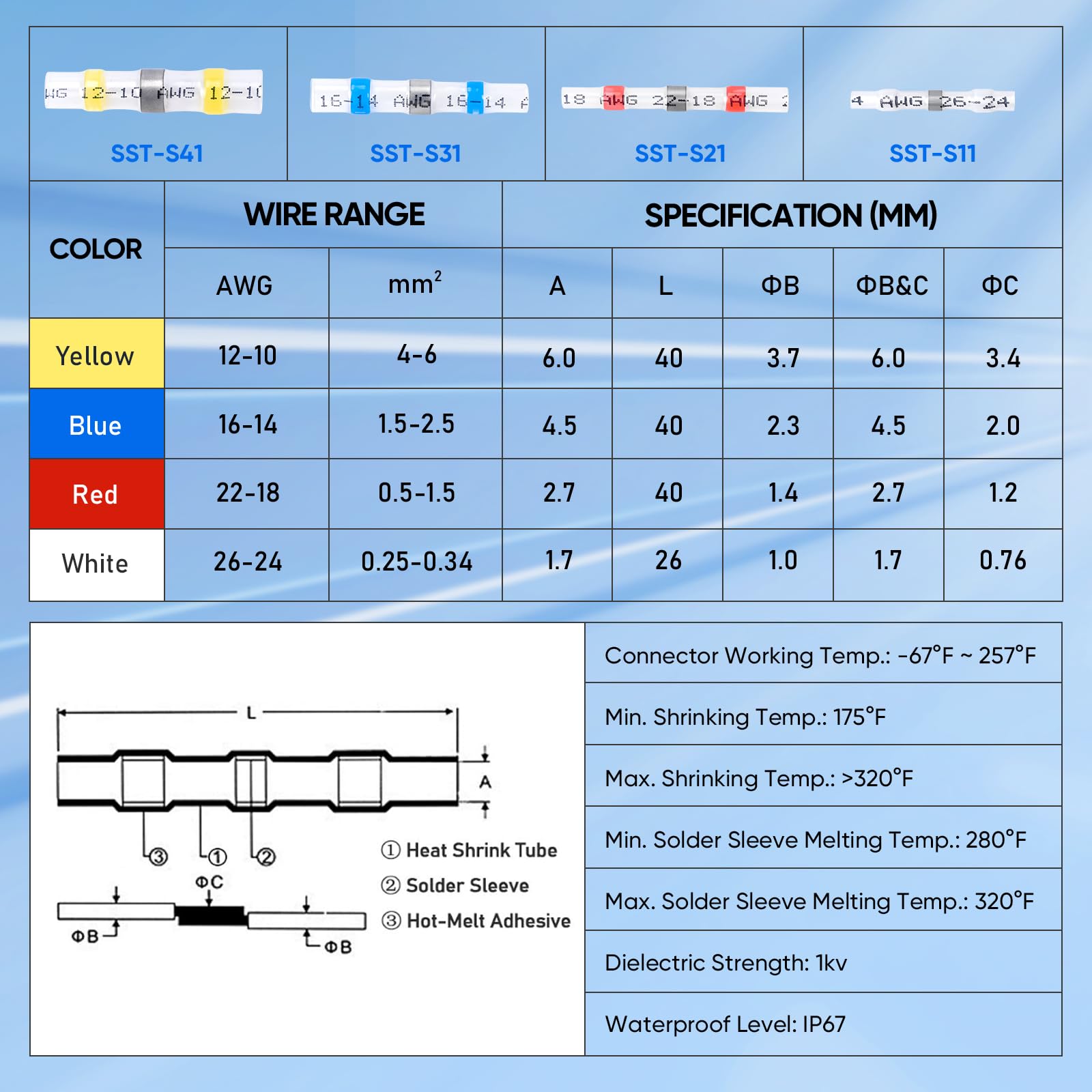

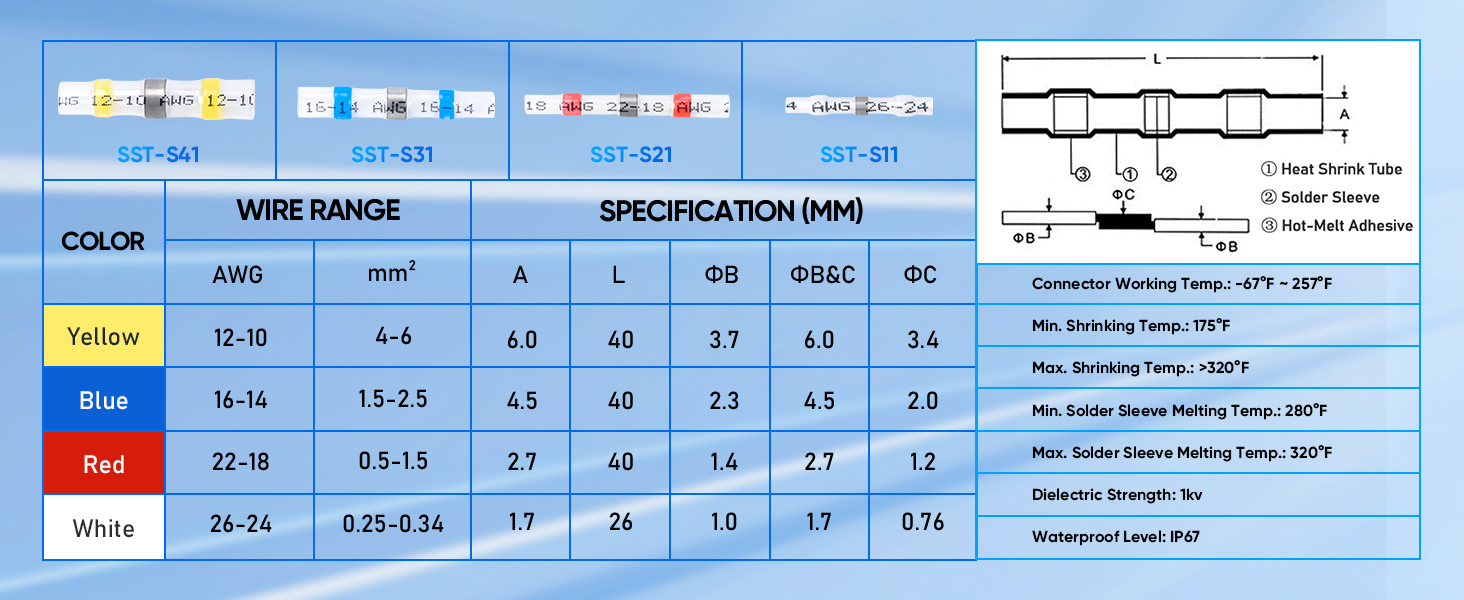

| Connector Type | Butt Splice |

| Terminal | solder,terminals |

| Brand | TICONN |

| Specification Met | CE |

| Temperature Rating | 125 degree celsius |

| Net Quantity | 100.0 Count |

| Manufacturer | uxcell |

| UPC | 757284205484 |

| Product Dimensions | 1 x 1 x 1 cm; 100 g |

| Item model number | TICONN - 101 |

| Manufacturer Part Number | TICONN - 101 |

| Item Weight | 100 g |

G**2

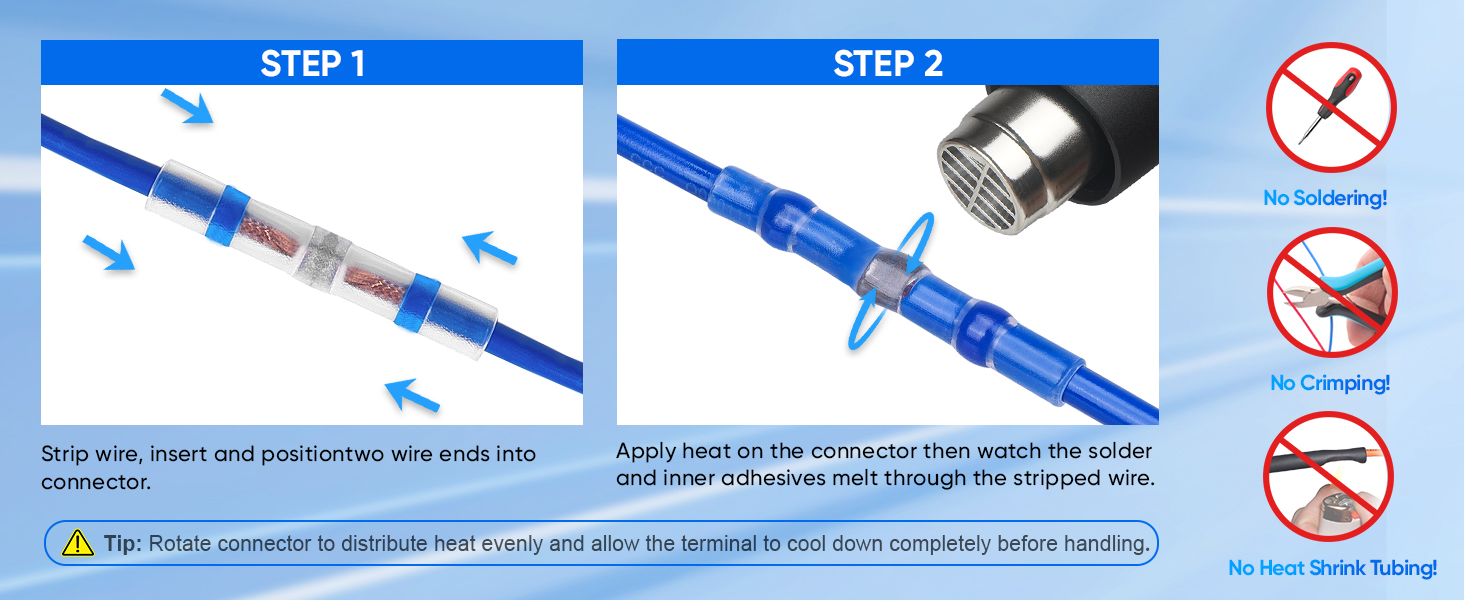

An alternative to tinning, soldering and shrink tubing

Nice to have in your repair arsenal. I installed a new water pump in my neighbors water fountain.The way it is set up, it's much easier and safer to splice in a new pump, rather than running a whole new power line. Connecting 2 wires went great, the third wire was in very tight quarters, so I thought I would try these new connectors. They work great. Shrink tubing over the whole cable. Voila!

R**R

Highly Rated

The biggest issue when using these is that you may be tying two wires together in a space where there is no way to hold the two ends and use the heat gun. That can be a problem. (Perhaps making a little jig with alligator clamps would help.) However, if you can overcome that, then the soldering works pretty well.Another way is to insert the connector onto one wire and wrap the two wire ends together by looping or twisting them back on themselves and then sliding the connector into place.This is not the cheap stuff, so it needs some decent heat to melt the solder. The average gun on high seems to take about thirty seconds to do that job.I would recommend this brand as others have.

H**E

Good for some connections, not others. Hard to hold in place while heating. Note Warning below.

Warning: Because it is difficult to hold both pieces of wire steady and straight (especially if your hands tend to shake a bit), I laid down the heat gun on its side on a metal table so I could simultaneously hold trigger and both wires in the connector. The box with the remaining connectors was about 2 feet in front of gun heat while the connectors were a few inches from gun. After successfully putting on first connector, I reached for another and discovered all my connectors had one side with the opening smaller than the other. I realized that despite the distance, just that little heat shrank the opening making inserting one wire difficult. So keep the box FAR AWAY from any heat as it takes nothing to shrink the outer covering.Other than that, the connectors were pretty simple to put in when connecting one wire to another. However, if you have two wires on one side and one on the other (or 2 and 2), the wires fit in the connector but do not cross each other under the solder so the connection will be suspect if the wires are too thick. e.g. I used 2 18G wires connected to 1 18G and that didn't work well in the red connector .An 18G and a 24G on one side and 18G on the other did work.Use copper wire (not copper covered aluminum which is what much of the junk wire seems to be from China these days) or the solder doesn't flow well. That's true of any connection but especially when not using mechanical connection before soldering. Mechanical connection means twisting the wires together before soldering.Note, my "Ease of Use" rating is a 5 for simple connections of one wire at each end but a 2 for more complicated connections or when doing multiple connections of two attached wires (like a lamp cord where both wires are attached and you can't separate them very far) because you have to do both attachments and heating at the same time as it is difficult to keep the already-soldered one far enough away and holding all those wires is a real pain.

N**E

Good for short wires

I used two for wires under my lawnmower's seat. The wires to the safety feature under the seat broke very near where they entered the connection. I tried to twist them together and use electrical tape but unsuccessfully. I was so impressed at the ingenuity involved in whole sealing process. So far, the connections have held. Now I'm trying to hunt down other wires that I've twisted together and "taped".

G**M

Works perfectly.

A great addition to your electrical wiring kit to take on all of your repair jobs. Good job.

Trustpilot

2 months ago

1 month ago