Customer Services

Copyright © 2025 Desertcart Holdings Limited

👟 Step Up Your Repair Game!

The Seeutek Shoe Repair Machine is a versatile manual cobbler sewing machine designed for stitching various materials, including leather and cloth. With a sturdy iron build, it offers easy assembly and low maintenance, making it perfect for home use. Its compact design allows for efficient storage, while the adjustable foot control provides precision in sewing, ensuring you can tackle any repair job with confidence.

| Brand | Seeutek |

| Model Number | SY-BZ-535 |

| Color | Green |

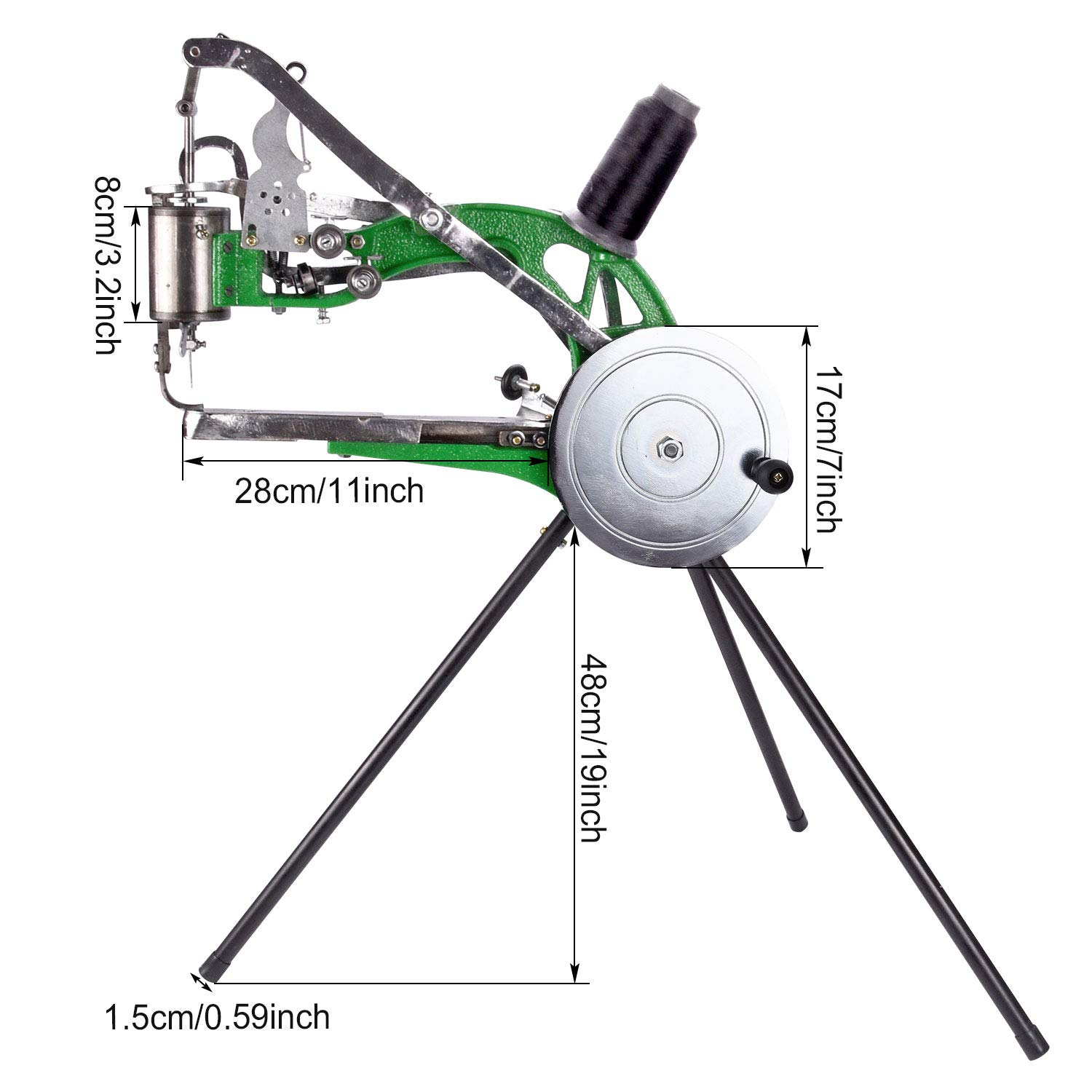

| Product Dimensions | 52.07 x 35.56 x 13.97 cm; 10.38 Kilograms |

| Material | Iron |

| Auto Shutoff | No |

| Item Weight | 10.4 Kilograms |

A**O

Chinamente Divertida

De la manufactura más "rudimentaria" pero al mismo tiempo muy funcional y divertida, jamás me imaginé divertirme tanto con una herramienta de trabajo rural como ésta. Simplemente hace lo que le pides y como lo pides. No le encuentro más definición que eso: CHINAMENTE DIVERTIDA

J**S

Garbage

Finish was peeling off, snapped thread constantly, mechanism didn’t work. I sent it back

N**P

WOW!

This thing is....great....kind of. See other reviews for a more in-depth description of what needs to be done to get this up and running. YouTube videos were the biggest help - there are a bunch out there. Definitely not ready to go out of the box - it takes quite a bit of TLC, but once the grease is wiped down, sharp edges filed, oiled, and mounted to a couple of 2x4s, it will go through just about anything that fits underneath it. I use it for leather - mostly 2 pieces of oil tanned 4-6 oz. I've found it to take a maximum of #138 thread - anything larger gets caught up in the bobbin mechanism and the thread breaks. The largest needle I've been able to find for it is size 22 (leather chisel from Bantam Tack and Saddle), which has worked flawlessly with #138 thread - both bonded polyester and bonded nylon. I've tried cotton, but with the tension needed for leather, cotton has consistently broken. So far I've gotten through a few hundred inches of stitching with the polyester and nylon without a single skipped stitch or broken thread. Beware of backstitching! This thing does not like it (which here is turning the presser foot around to go in the opposite direction over your previous stitching). I've only been successful about half the time. Thread tends to get knotted up in the bobbin mechanism - I end up just hand sewing a few back stitches (saddle then knot it off). In sum, takes some effort, but then it's basically a low grade industrial sewing machine for 1/10th the price of an actual industrial machine.

F**

Buena compra,

La máquina funciona deacuerdo a lo que el fabricante promete. No me doy 5 estrellas por que requiere ajustes como limar filos de algunas piezas que afectan su funcionamiento inmediato. Es una gran compra costo-beneficio. No la recomiendo para principiantes sin experiencia en costura a maquina. Con algun vídeo en internet puedes ponerla a punto sin ningún problema. Funciona bien

H**H

needs some work but can be good

it is a good buy for $130. You wont find anything like this, anywhere near this cheap.However : i would not buy this unless you are mechanically apt and have some patience and are willing to take a 75% complete product to finish. you will need to make some minor changes and modifications for success with this machine. it works as-is out of the box, but its behavior is not consistent. inconsistency in a machine can wreck a sewing project.View this as buying a project, it will be a sewing machine in one afternoon of work and care, but you must have an open mind and some patience for it to shine. It has lots of levers, cams, and rotating things exposed, and these all can be adjusted, mis-adjusted, and mal-aligned from bumps.mine arrived banged up in shipping. the machine itself was covered in a mixture of oil and rust slime. only the top part of the frame was painted, the sides were not. Packaging is a styrofoam clamshell - however the oil on the machine dissolves and melts the styrofoam , leaving missing holes in the packaging material/clam-shell . the cardboard box it arrived in was covered in one side with oil stainsProblems:- instruction manual needs work, it is translated but does not seem to be well reviewed, it takes a bit of thinking to understand the peculiar word choices.- greasy and rusty - lots of half rust, half grease slime in the machine, with casting sand and grit mixed in. i used some automotive spray cleaners to wash out the crumbs and old grease, and put new oil in. it took some time to get all the sand out , bearings do not like sand.- walking foot cam does not have a rolling bearing, instead it is a metal-on-metal high friction/dragging action which makes the machine tougher to use and will result in premature wear if used heavily. must be well greased here, clean and replace grease with regular use.- thread feed areas are too rough, sharp corners instead of round corners. can contribute to thread binding or bunching- no good way to feed thread - you will need to have your own thread & spool hanger to have thread pulled off the spool smoothly, the machine is set up to pull off the spool from its side which can cause erratic stitching due to friction of the spool rotating against the body of the machine. heavier spools cause more drag and binding- included tripod stand is awful, machine wobbles too much. i made a wooden base out of scrap wood in a V shape to hold it up, with a couple pieces of 2x4 to lift the body up, the crank wheel needs lots of clearance space.- casting design defect near main crank bearing, casting wall support for the bearing is *very* thin (2 or so millimeters) and may crack and develop frame failure with age. it is a design compromise to allow the use of a smaller crank wheel. It may be just fine as-is, the crank wheel is intended to be operated by hand. However, i would consider this point heavily, if i were to want a treadle-belt drive conversion or an electric motor added on. i do not believe this machine is built well enough for any sort of speed.- no clear marking/indicator of shuttle position, sometimes if you take the bobbin out you can remove the shuttle with it by mistake - alignment is annoying until you learn where it should be. I marked mine with a small file, scratched a notch in the body and shuttle as an alignment mark.- pain to thread , you have to run thread down the head of the machine through a roughly machined slot , the thread gets stuck in this slot. i tried using a pipe cleaner and it gets stuck too, found a good solution to be heavy string/weed trimmer , (a long solid piece of plastic wire 2-3mm dia )- no thread lock in bolts/screws found on small moving parts - one of the levers for the needle action works itself free, its a small phillips head with a two piece C shape clamp located on the head of the machine, just above the vertical shaft driving the needle - this screw and clamp has worked itself free from vibration twice. I had to clean it and use a small amount of thread-lock on my second attempt. it has not since worked itself loose. I recommend this as an initial precaution, if this clamp/arm works itself free during use it could break or snap.- replacement shuttle and bobbins do not line up - the replacement shuttle i was sent is mis-shapen and was not made correctly- unpainted bare cast iron - this will rust if in a humid environment, musty closet, or touched and handled often.good:+ rotating head & walking foot , can turn the entire sewing mechanism and direction relative to the frame/arm - makes for repairs in coat arms. rotate the sewing and needle, no need to rotate the project around the machine.+ bobbin mechanism easy to wind and service - takes some practice to properly tension bobbin during winding+ cheapest sewing machine you'll find that actually works. no plastic gears, or rubber belts to fall apart.+ can use unreasonably heavy thread - thread is fed down in-line with needle on the same plane, so any tension forces pull the needle up and down, not sideways. heavy thread or solid plastic thread can be used without needle breakage.+ can sew heavy materials - lots of supportive material in the sewing head , no wobble or flexing. lots of steel, cast iron.

Trustpilot

2 weeks ago

2 months ago