Customer Services

Copyright © 2025 Desertcart Holdings Limited

❄️ Cool tech, hot performance – stick with the best!

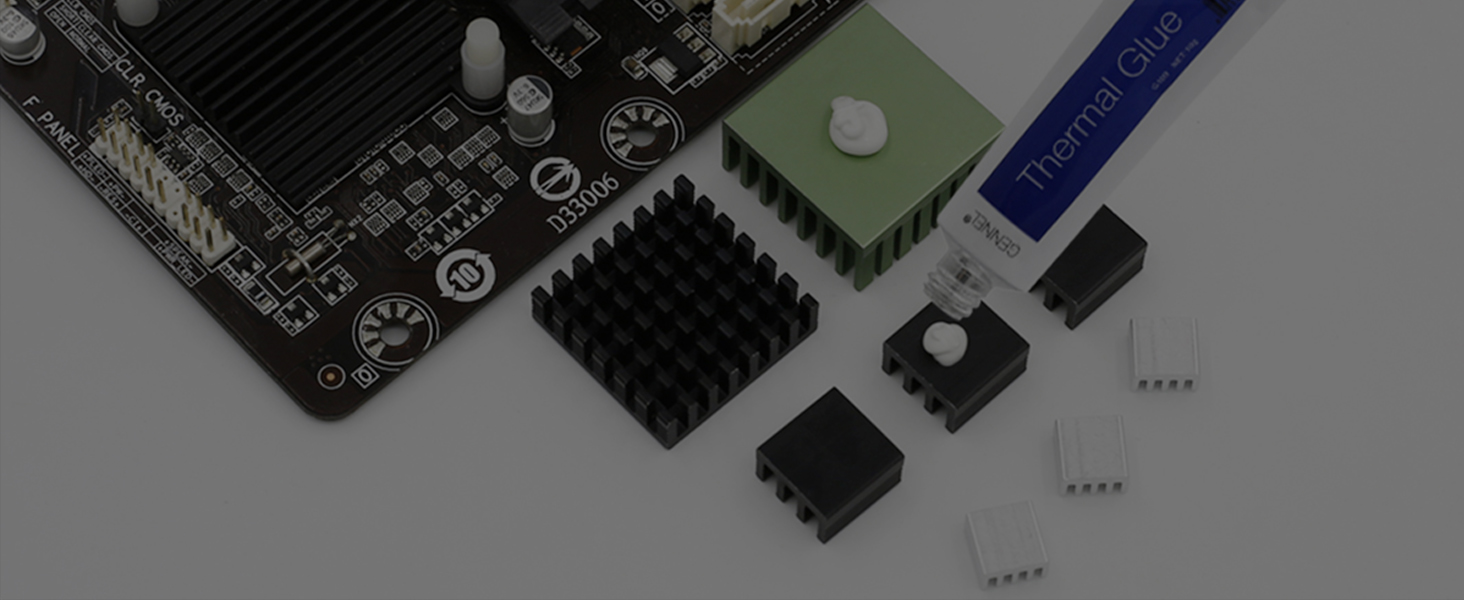

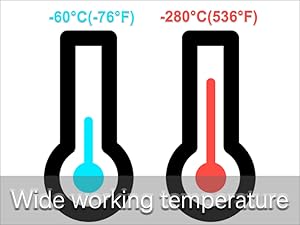

The GENNEL 10g Thermal Conductive Silicone Plaster is a viscous adhesive compound designed to efficiently transfer heat away from critical components like GPUs and LED chipsets. With a strong bonding capability and a compact 10g size, it ensures reliable cooling and secure attachment of heat sinks, making it a trusted choice for high-performance electronics and crypto mining rigs.

| ASIN | B072MSXHJD |

| Batteries Included? | No |

| Batteries Required? | No |

| Best Sellers Rank | #42,323 in Computers ( See Top 100 in Computers ) #74 in Thermal Paste |

| Color | ice |

| Customer Reviews | 4.5 4.5 out of 5 stars (1,008) |

| Date First Available | 30 November 2017 |

| Item model number | GENNEL G109 |

| Material Type(s) | Resin |

| Number of Puzzle Pieces | 1 |

| Product Dimensions | 9 x 7 x 1.6 cm; 10 g |

S**H

Works as advertized. (I used it to glue and seal a heat exchanger). Takes a few hours to set and forms a strong bond. Would help to have detailed spec sheet giving thermal conductivity.

D**S

Had to use this with an crypto miner that needed new heatsinks and never experienced a problem since then

D**N

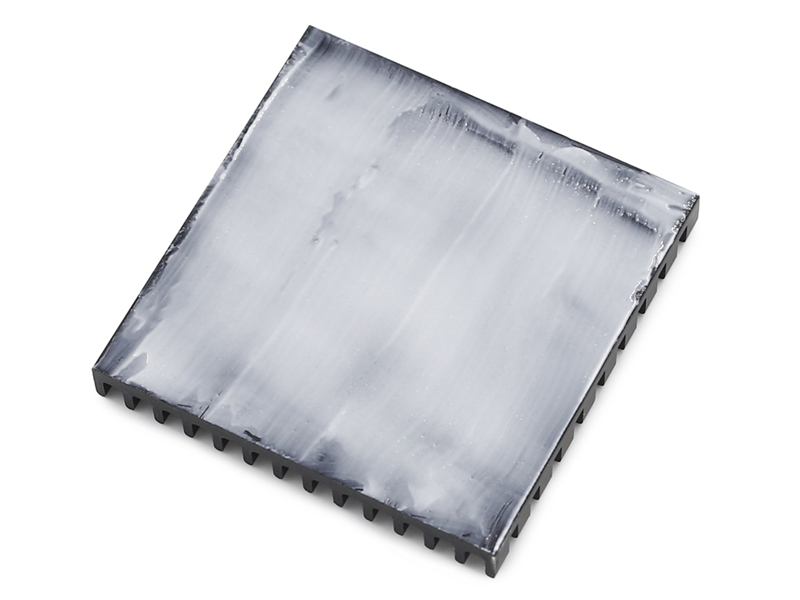

I purchased this adhesive in June 2018 and first used it over the past couple of days to assemble homemade heat sinks and apply them to NVME SSDs. Before bonding parts I applied the adhesive to lapped 1/2" square pieces of 1/16" thick aluminum 1100 and applied moderate pressure. A joint gap of .001" was measured with calipers. At a thermal conductivity of 1.2 W/m-K, this bond thickness has neglible thermal resistance for my application. Bonding of parts was done at a humidity of ~30% and a temperature of ~70°F. The adhesive did not "skin over" or otherwise exhibit an increase in viscosity during the fifteen minutes or so that I was working with it. I prefer a slower curing adhesive so that I do not have to race to get parts assembled before increased viscosity causes problems. This applies in particular to parts being bonded to circuit board components since large clamping forces have the risk of damaging the circuit board. Silicone (polysiloxane) adhesives require moisture to cure and this moisture can be provided from the atmosphere or adsorbed moisture on surfaces that are being bonded. Thin joints will cure faster than thicker joints. If you are not going to be able to leave the bonded parts alone for at least 24 hours, it is a good idea to bond pieces of scrap metal and/or plastic and test the bond strength of the test pieces prior to putting your bonded assembly into service. Cleaning surfaces to be bonded with a cotton swab and isopropanol and/or acetone (not suitable for some plastics) is also recommended since the solid filler used to enhance thermal conductivity inhibits the flow and wetting capability of the silicone adhesive. TANSTAAFL. Two pieces of copper were cleaned, bonded, and tested after a 24 hour cure (see photo). The lap joint (~.3 sq.in.) held up under the application of a 10 pound shear force, but failed at 20 pounds. The adhesive in the interior region of the failed joint was still plastic, indicating that the joint wasn't fully cured; however the bond was strong enough for my application.

A**R

Worked great 👍 👌

M**Z

Used this to secure 3w UV LEDs to mounting chips and heat sinks. Worked like a charm even in an outdoor environment. Only a single drop was more than sufficient to secure each LED to the chip and each chip to the heat sink (although solder and glue also connected the devices). The glue also seems to help to promote thermal transfer.

Trustpilot

5 days ago

2 weeks ago