Customer Services

Copyright © 2025 Desertcart Holdings Limited

Desert Online General Trading LLC

Dubai, United Arab Emirates

🚀 Unleash Your Creativity with Precision!

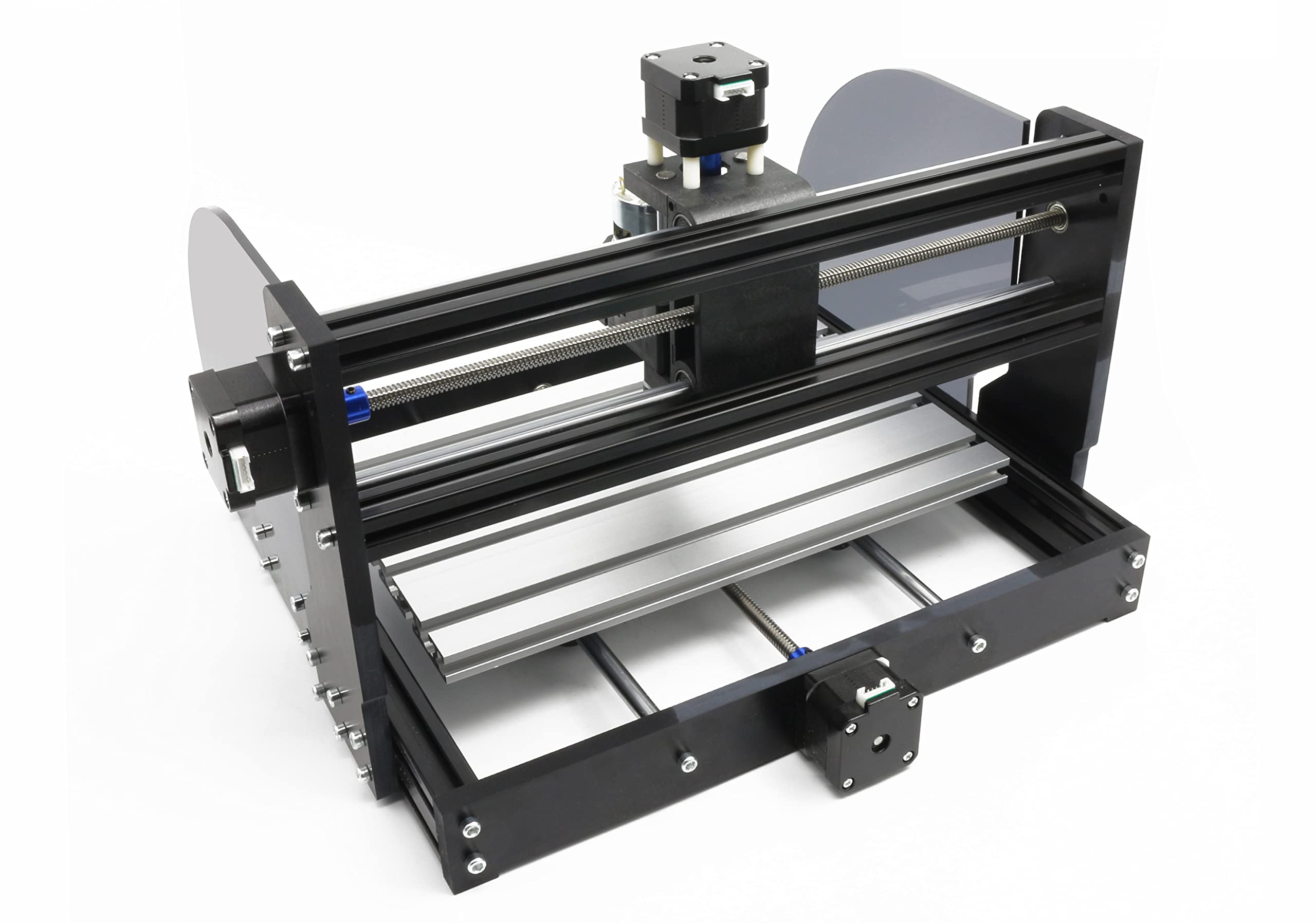

The RATTMMOTOR CNC-3018-PRO MAX is a compact and powerful CNC router machine designed for DIY enthusiasts. With a working area of 300x180x45mm and a maximum spindle speed of 20000 RPM, it can engrave a variety of materials including wood, plastic, and soft metals. The machine features a user-friendly assembly process, advanced GRBL 1.1 control board for safety, and is built with durable aluminum and stainless steel components.

| Brand | RATTMMOTOR |

| Material | Aluminum |

| Power Source | Corded Electric |

| Product Dimensions | 16.54"W x 10.63"H |

| Voltage | 24 Volts |

| Maximum Rotational Speed | 20000 RPM |

| Amperage | 13 Amps |

| Base Type | Fixed |

| Battery Description | Corded electric |

| UPC | 619191754908 |

| Manufacturer | RTM |

| Part Number | 3018Pro-M+ |

| Item Weight | 15.45 pounds |

| Country of Origin | China |

| Item model number | 3018Pro-M+ |

| Color | 3018pro-max |

| Style | 3018PRO-MAX |

| Batteries Included? | No |

| Batteries Required? | No |

| Description Pile | Corded electric |

Trustpilot

3 weeks ago

1 week ago