🔥 Elevate your craft with precision power and pro-level versatility!

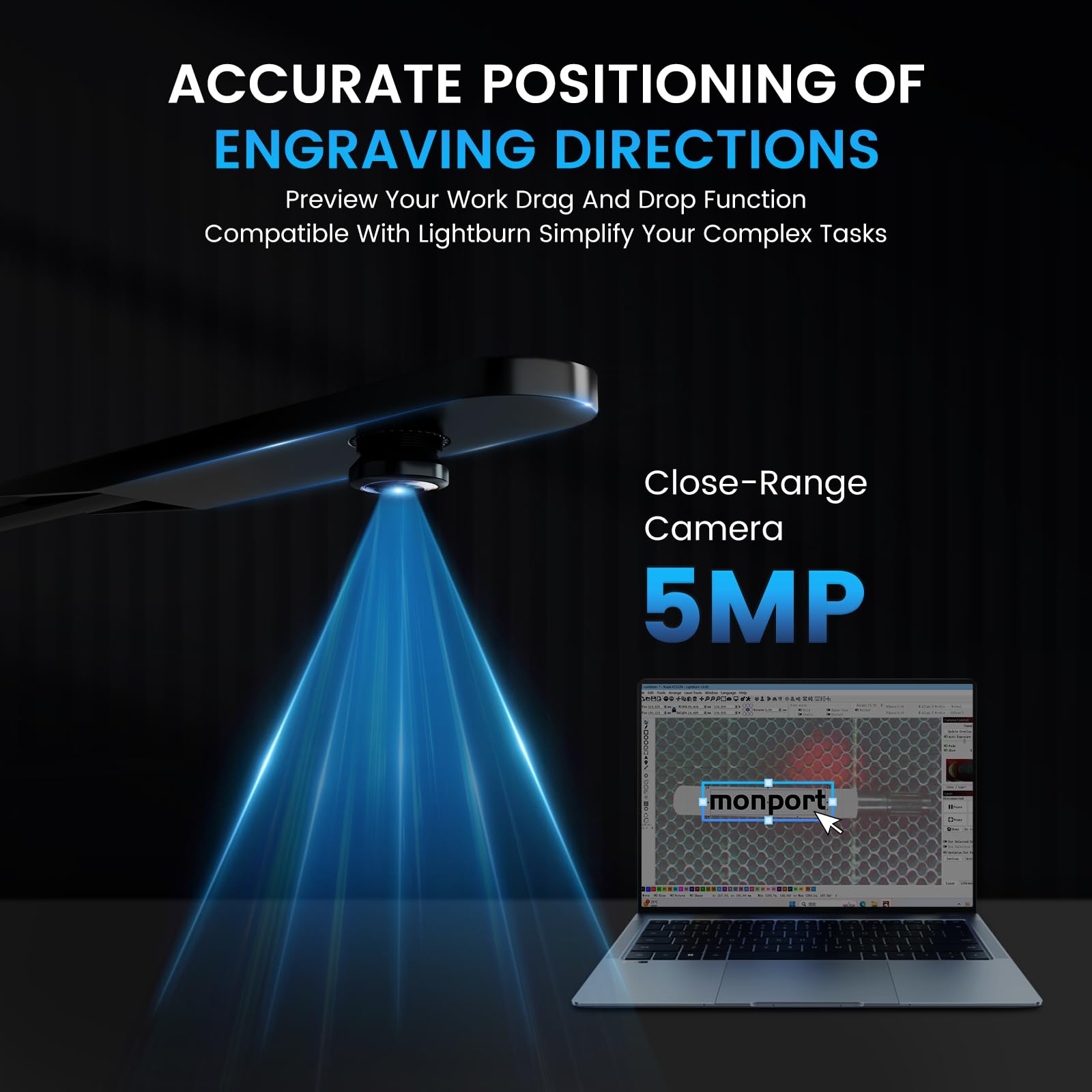

The MonportOnyx 55W Desktop CO2 Laser Engraver & Cutter delivers professional-grade cutting and engraving with a powerful 55W laser, a spacious 20x12 inch workbed, and a 5MP camera for precise design alignment. Featuring auto-focus, rotary axis, and pass-through capabilities, it supports a wide range of materials including wood, acrylic, leather, and ceramics, making it ideal for creative professionals seeking speed, accuracy, and versatility in one compact machine.

A**M

bought this January 23, 2025, Has been working great but now 7/27/2025

bought this January 23, 2025, Has been working great but now 7/27/2025 the unit is leaking coolent (Right side) right over the power supply and the main controler unit. Everything now has shorted out not sure if the c02 tube is bad or not. The laser is now JUNK. I sure do hope that someone from Monport will reach out to me to get this unit up and running again. Was NOT my fault the cooler hose leaked! Please Monport I need this laser working I have many jobs that need to get done... Please and thank you.

Y**8

Exelente producto

Exelente

A**R

The little things where a pain.

First off the laser came sooner than I expected. Laser was well packed. When I removed it and with help put it on solid surface. I took out all the installationfrom inside and pulled down the lid to shut it. The lid was binding on the left side and it would not close. I contacted support who was very responsive, I was happy about that. They told me to level it (didn't work) , put support on one corner ( didn't work). I ended up filing down the side next to the lid, which solved the problem and it looks fine. Next I was doing camera alignment and the laser head would bind and stop on the rail, it did it 3 times in a row. I looked with a flashlight , but couldn't see a problem. All of a sudden a very small screw fell down from the rail onto the bed. I picked it up and it appeared to be the same size as the screws that mount the guide rails, I looked every where but couldn't find where it came from. I ran the job again and every thing seems to be working. Only thing I can think of is that's it's an extra screw? Conclusion: the laser is pretty awesome but somme thing like this shouldn't happen. I would still recommend this laser. Camera on this is lake the xtool where you can simply drop a piece on the bed and line up the cut on your laptop.One bummer is it went on sell same day it was delivered, I ask for the discount, but I'm not holding my breath.

C**Z

Solid Frame and Crisp Cuts… Customer Service Needs Help

Original Review: It arrived yesterday and I got it unpacked and set up late last night. First off, this thing is really sturdy in construction. Second, once I pulled down Lightburn it was fast and easy detection of the Onyx 55 with the software, and I was doing test cuts on one of the many included materials sheets that came with it! Super easy to dial in just what you want and start both cutting and engraving (fills). I’ll add images and maybe video later, but I wanted to share our amazing experience so far with this machine. It’s got pass-through for larger materials, so for the price it’s literally the best value I’ve found out there for a desktop CO2 - and it comes in a 55W when other ‘comparables’ come in at 50W and way more expensive! Great gift for myself, but also I get to start up a fun side business with the kids!UPDATE: First off, let me say I returned this unit (within a week) and now removed two stars from my five star review… here’s why:1) The current Monport customer service across all channels (FB, FB Messenger Business Chat, Web/Email, and here via Amazon chat) is abysmal. The best was via Amazon chat and that’s only because I filed a complaint and magically I started getting responses on literally ALL other channels.2) They don’t seem to have domestic US support personnel that work US hours, so catching up with them is challenging.3) Documentation is currently sparse. Setup information is really nonexistent, save The Laser Channel setup video, which they now use directly on their website), but unless the same content creator makes more vids, users are left in the dark for the most part.4) Even when exceeding the camera setup tolerances, the fisheye camera overlay on the work area in Lightburn is very inaccurate. It makes for a poor experience when positioning start/stop points with camera assistance.5) The unit came shipped with coolant IN the cooling reservoir - which is normal for most now that I’ve researched - BUT whether due to mishandling during shipment, packing issues/leak, or it not being filled properly at the factory, the levels were low and immediately caused the coolant pump to make noise and churn up a lot of air bubbles inside the laser tube, which was clearly bad. Upon recommendation by again the awesome Laser Channel (and frustratingly NOT Monport though I tried reaching out), this was fixed by adding some distilled water into the reservoir.6) The pass-through experience was/is disappointing. According to the Monport FB business chat, “We don't have auto-feeder, we only have auto-pass through.” Even if this is a lost in translation, it just highlights my #2 point above. While the Onyx 55 has REAL cutout ports for passing through oversized material that many of its competitors don’t have, it’s MANUAL only. You will need to measure carefully when working with long material.All that being said I wish I could have kept this machine. I believe that with more domestic customer service support, WAY better documentation, and a larger community that communicates best practices, the Onyx 55 could be a fair contender for beginners - ESPECIALLY since you can get it for around $2k with the rotary included when it’s on promo! I have since bitten the bullet and gotten their much more expensive competitor unit (by 200%), but it does curved surface engraving and the pass-through has true auto-feed.I wish Monport and all of you the best with the Onyx!I truly believe you have a great machine here, and look forward to your development with it in the future! Maybe we can try again soon!

O**Y

Everything needed to start cutting.

My first co2 laser, bought because of price, works like a champ! The software it comes with is a bit limited, but it is free and works vs spending another $120 for lightburn. The manual is a bit underwhelming but was able to find a decent video walkthrough to get me going.

L**C

3 Month old Onyx 55w - power keeps cycling on / off

3 month old Onyx 55w laser. This morning when turning on it would light up for 1 second, then off for like 5 seconds, then repeat.... I see from other reviews that it's not easy contacting support, I opened a service support ticket. Lets see what happens. In the meantime if you've experience this let me know what happened to get you up and running again.

Trustpilot

1 week ago

5 days ago