🚀 Elevate Your CNC Game with Precision Power!

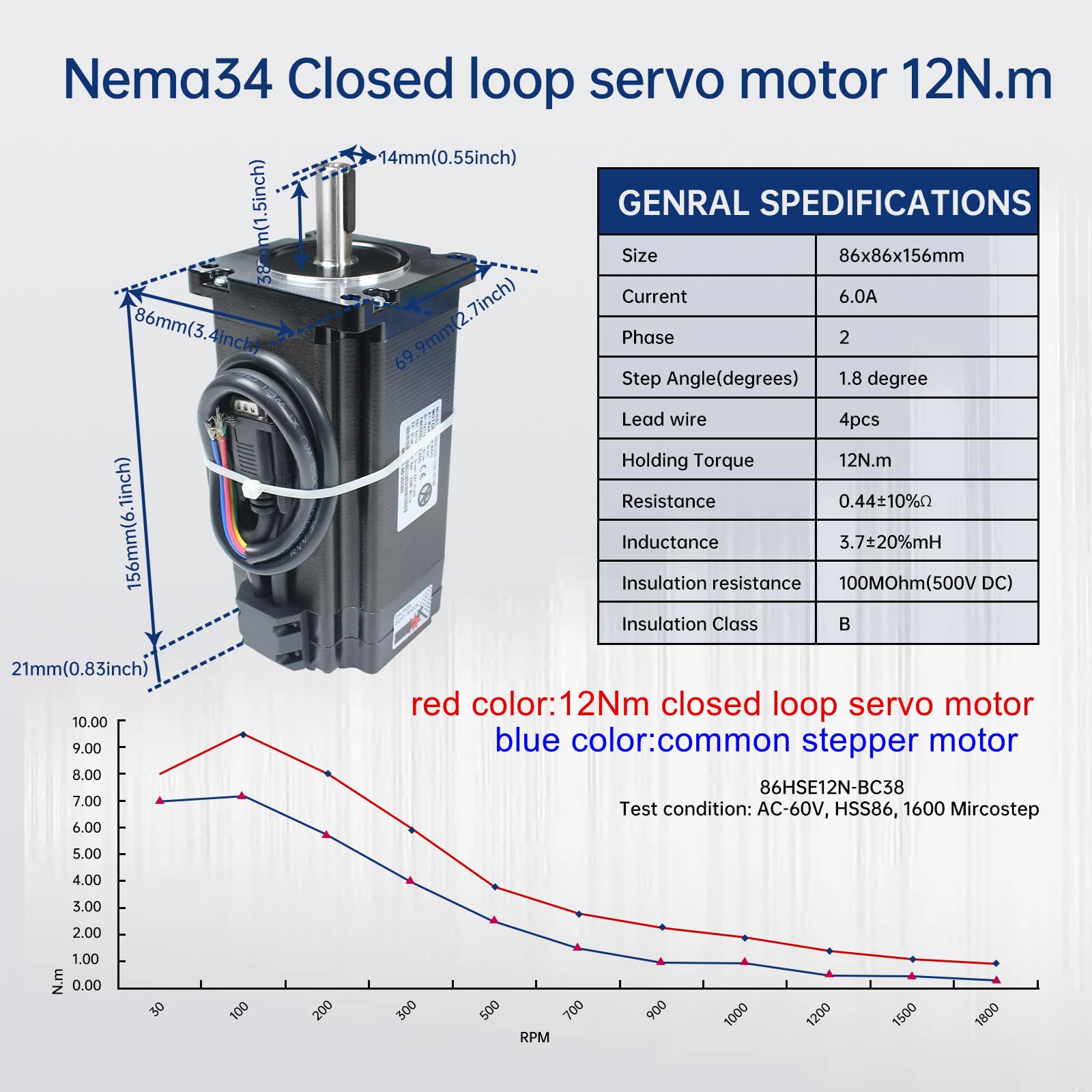

The RATTMMOTORNema34 Closed Loop Hybrid Servo Motor Kit combines a high-torque stepper motor with an advanced servo driver, delivering exceptional performance for CNC applications. With a holding torque of 12N.m and a rated current of 6A, this system ensures precision and reliability. Its versatile design supports various machinery, making it an ideal choice for professionals seeking efficiency and safety in their operations.

A**I

Great little Motor

I used this in a fully automated durability test, at work, where it ran a 6" butterfly valve open and closed. A PLC was used to automate the test. To drive the butterfly valve, a 90deg gearbox and some shafts were used.The main reason I bought this motor was because it had a Torque vs Frequency graph, which is almost spot on. I used that graph to calculate which planetary gearbox reducer I would need, so, I could get the correct output shaft speed and torque for our test. The torque output was verified through the use of a torque transducer and a data acquisition system.The test was setup to have the motor stall out at a predetermined torque when it reached the end of the butterfly valves travel, 20.7 ft-lbs or 26.5 ft-lbs, dependent upon which portion of the durability test we were at. It was stalled over 10,000 cycles before the test completed.The motor was run like this for about a month and a half. Keep in mind that there was some downtime for maintenance and inspections throughout the test, so it's not like it ran for a month and a half straight. During this time the motor didn't receive any maintenance, just our test specimens. The test also wasn't run over the weekends either.I'm impressed it was able to take that many stalls without any issues. The motor still ran fine at the end of the test. The output shaft was still tight in the housing without any side to side motion. It didn't over heat. Overall, it's a nice cheap durable motor.

A**D

Closed-loop, adjustable steps per/rev is AWESOME!

I got just one of these to test before buying 4 more. In short, after bench testing the driver together with a 1.8 degree step motor and 1000ppr (line) encoder works very well and the closed-loop feature performs as expected. Please read on for the long version.This RATTMMOTOR HSS86 is manufactured by Changzhou Jinsanshi Mechatronics Co. Ltd. (aka- JSS-Motor) and is sort of a knock-off of a Leadshine HBS86H. It's not faithfull replication internally (see pics), but on the outside the two look almost identical.Functionally the HSS86 and the HBS86H differ just a bit:In my test of the HSS86 the postional error correction was linear and delivered a smooth and even response during corrections.By contrast in my other test the HBS86H had a correction strategy that is very aggressive, meaning that in my test the driver ramped the current up to the max available for the first 20 degrees (appx) of shaft error. When even more degrees of error were present the current dropped to a nominal level. The effect was that the motor put up the maximum fight to correct for about 20 degrees and when the error was greater than that the motor weakened its effort to correct.In some ways I like the HSS86 better for when mechanical componants shouldn't be exposed to excessive torque. An example is an 8 foot long ball-screw could fail (shear) if its ball-nut was farthest away while a crash was occurring... 80v 4-stack nema34 motors deliver over 1700 ounce/inch of torque. That's strong enough to break things.Both drives have an RS232 port for programming, but the HSS86 can only be accessed by the manufacturer. This I learned from contacting them directly.The HBS86H can be user configured via the port, but in my several attempts I could never get the Leadshine ProTuner software to connect with the (stepper) driver. This is disappointing as I would like to access to the many parameters that supposed to be available.Whether HSS86 or HBS86H both do a really great job of converting a stepper into a closed-loop servo motor. The DIP switches on the drives will set the step resolution much higher than any standard (Gecko or otherwise) stepper drive. It's really cool to see how smooth a step motor is at 8000 steps per/revolution, or even higher. They also both have signal outputs for both positional error and drive error conditions (very cool!). These outputs are essential to connect to the motion controller which will allow the CNC app to halt the machine when the real position does not match the indicated position (of the user's computer) or when the step driver is in "fault" (over current, over voltage, etc.).I'm using these drives with my own motors and encoders, for those doing the same it's super important to know that these drives "only" work with 5vdc 1000ppr quadrature encoders with differential (a+/a-, b+/b-) output. This is not problem as it is a popular encoder configuration, it's just that anything else won't work. If you buy a driver with motors included you'll not need to know this.HSS86 (w/nema34 motor)Nema34 4.5N.m Closed Loop Servo Motor Stepper motor 82mm 6A 2 Phase & HSS86 Hybrid Servo Driver Controller CNC Kit for CNC Router Engraving Milling MachineHSB86HLeadshine DSP Closed-Loop Stepper Driver HBS86H 8A 30-100VDC Easy Servo Drive ES-D1008 fit 86mm NEMA34 motorI can't see anything cheap or wrong with the HSS86 or the HBS86H and I'm impressed with the Texas Instruments 32bit microcontroller (TMS320F28034) that's in the HSS86, I suspect the same chip is in HBS86H but Leadshine decided to media-blast the ID from the chip (see pics).Only time will tell how well these drivers survive on my 80vdc, 8amp system. I've had great experiences so I expect the same, but I will update this review as time marches on.

J**H

bien¡

Recibido, muy rapida entrega por el momento todo se ve bien

B**R

Suspect Timing. Died right after the return window closed.

UPDATE: The Seller was very attentive to my plight. So I'm trying another exact setup and hoping the one I got was an anomaly. Even if I have the same problem, good customer service goes a long way.The motor was great. Now it's just an expensive useless thing. The driver faults and flashes RED and, of course, the motor doesn't move anymore. NOTHING has changed on my end. It was working this morning and now it's not. It's extremely suspect that the return window closed a couple days ago. DO NOT BUY IT!

L**

A professional CNC stepper motor

Spend extra, get closed loop! Was really easy to install! (I'm not even a professional CNC'er.)I have this motor for about 3 years now. I'm still very satisfied. speed and torq in abundance.Learn to use the switches on the stepper driver to get faster speeds

M**M

DO NOT TRUST STICKERS

Product worked great, that is, AFTER spending 20+ hours debugging with an oscilloscope, which you may or may not be fortunate enough to have. Finally discovered that the sticker on the motor gave wrong information, the poles on the motor were switched. This wouldn't be as much of an issue to debug if the motor was a normal stepper, but the switched A+ and A- poles made the driver immediately go into an alarm state whenever you give it step/dir pulses. Absolutely maddening, but now that's cleared up they've been working great and delivering on all their claims. Would recommend, but definitely with a disclaimer.

E**H

Great motor/driver. Get the manual!

Great motor/driver setup. Make sure to message the seller for the user manual when you order, that has the correct wiring diagrams and will make setup a breeze. They got back to me in just over 24 hours. The encoder is very helpful when testing out your machine and seeing just what it can do. I got it to fault out when trying to find my max acceleration.

S**N

Watch wire color listed on motor

Great unit once working ,,,Beware the encoder wiring has blue and black EB + and - listed in reverse ,, it only will work when you swap them ,, blue and black on the encoder hookupOtherwise a very nice unitCustomer service is excellent in the weekdays

Trustpilot

3 weeks ago

4 days ago